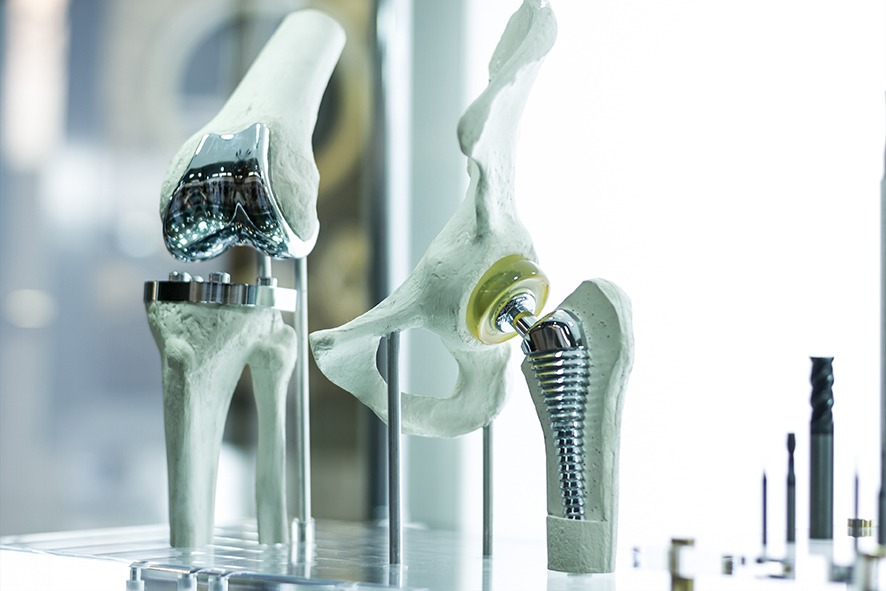

In May 2021, the European regulation on medical devices comes into force. Faced with new challenges, NGL wishes to contribute to the evolution of safer medical device manufacturing.

As a detergents provider, NGL is at the heart of risk management and endorses its customers’ concerns:

- Are the detergents used in compliance with the regulations? Will they remain so?

- Is my supplier able to provide me with the necessary data for my risk analysis?

- Is the quality of these detergents controlled over time?

- Can my supplier support me technically?

To answer these questions, NGL has based its approach on 4 levels:

- Regulatory and normative compliance

- Sector expertise

- Cleaning and process monitoring

- Quality enhancement

Regulation

Our new references have been designed with carefully selected elements to anticipate regulatory changes and facilitate risk assessment. Any substance suspected of presenting a CMR hazard has been ruled out. In addition, NGL has carried out a “screening” of the inorganic elements in this new range, to help our customers in their biocompatibility validations, in particular ISO 10993-18.

Expertise

In addition to regulations and standards, NGL’s approach includes knowledge of materials and the specifics of MDs. Passivation is a good example of the difficulty of this approach: What process should be recommended for passivating X20Cr13 steel, which is more sensitive to corrosion? Extending its collaboration to other players in the production chain such as suppliers of abrasives, lubricants, cleaning machines and analysis laboratories has enabled NGL to come up with new solutions.

New range

- Rubifin N°4

- Rodaclean 2018

- Decoclean 440

- Galvex 20.01

- Decospray TM

- Decomet

The NGL range is designed to be readable, compliant and of course effective! This simplification has been made possible thanks to the investment and coordination of all NGL’s departments: R&D, the production/HSQE department, the purchasing department and finally the sales staff. Aware of the problems of the medical sector, they have made it possible to synthesize sometimes contradictory orientations: efficiency, availability, cost control, regulatory compliance.

This range is also intended to be versatile, making it possible with a limited number of products to treat almost all cleaning problems in the medical sector: various types of pollution (polishing pastes, lubricants, etc…), materials (austenitic and martensitic steels, polymers, ceramics, titanium, etc…), cleaning stages: interoperation, finishing, surface preparation before passivation or decontamination.

Quality enhancement

Although quality has always been a priority for NGL, we have become aware of the need to better communicate this requirement. ISO 9001, ISO 14001 and ISO 45001 are not just labels. They are the foundation of the quality of our products. In addition to this, there are multiple stages of control. In addition, NGL is engaged in a process of continuous improvement to bring ever greater control and quality to its products.

Evolution

From now on, NGL is looking to the future and is planning, among other things, the development of a phosphate-free range and is preparing for the entry into force of the CLP regulation on the Unique Formulation Identifier.

Contact us for a presentation, information on our products, an audit of your cleaning process, on-site or remote training.