THE ROLE OF AN INDUSTRIAL WWTP

Before explaining how an industrial WWTP works, we need to explain its role. Obviously, the aim is to clean up water and, indirectly, soil, but these plants target specific pollutants that could interfere with the operation of a municipal wastewater treatment plant, whose main purpose is to treat domestic and largely biodegradable wastewater. This is why these plants use biological treatment: bacteria, in the presence of oxygen, degrade organic contaminants: grey water, black water (from kitchens, bathrooms, etc.).

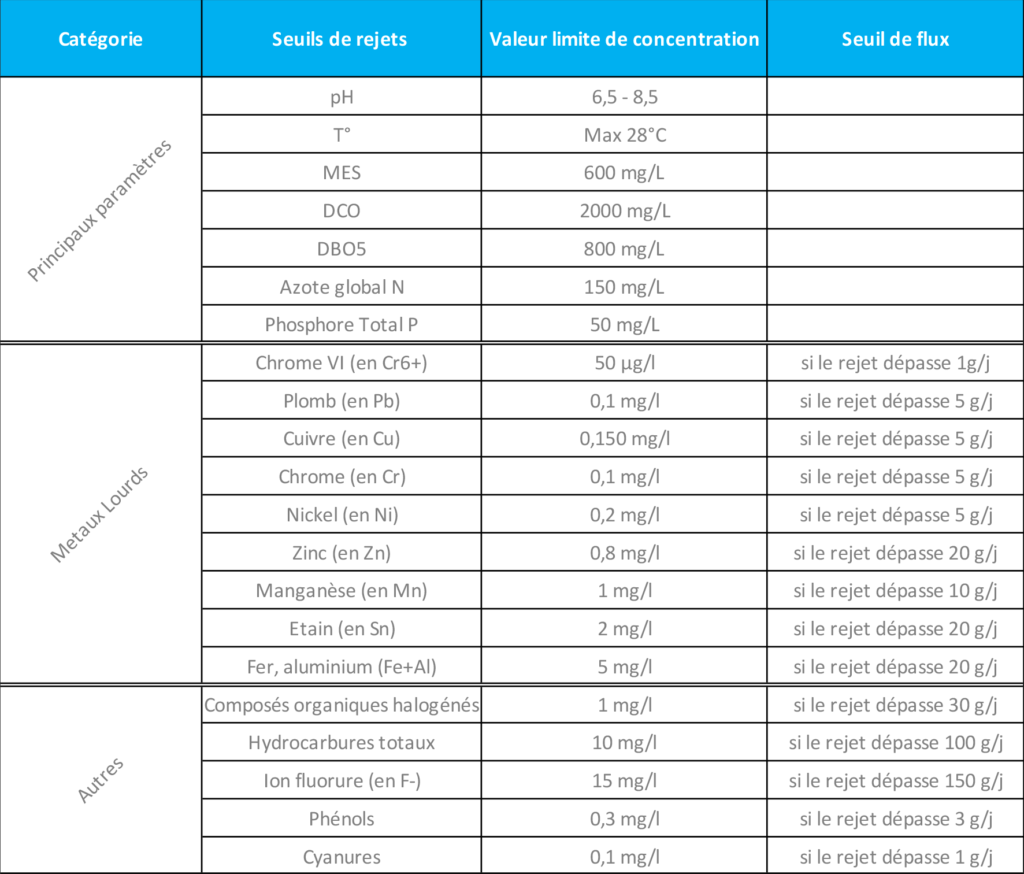

The following is a list of pollutants measured in connection with a connection permit application, and which may interfere with the operation of an agglomeration WWTP, either because of their toxicity (heavy metals accumulate in the sludge, which can no longer be used for agricultural spreading), or because they generate too high an oxygen demand (COD and BOD5, made up, among other things, by laundry detergents), which would asphyxiate bacteria, or because a conventional plant cannot treat them (as in the case of phenols).

DISCHARGE THRESHOLDS FOR INDUSTRIAL WASTEWATER TREATMENT PLANTS CONNECTED TO THE SEWER SYSTEM

Order of 2 February 1998 on the sampling and water consumption as well as emissions of all kinds from installations classified for environmental protection subject to authorization (source)

The industrial WTP aims to eliminate some or all of these pollutions.

OPERATING PRINCIPLE

Main pollutants : COD, BOD5, Nitrogen, NTK, Phosphorus, SS, pH

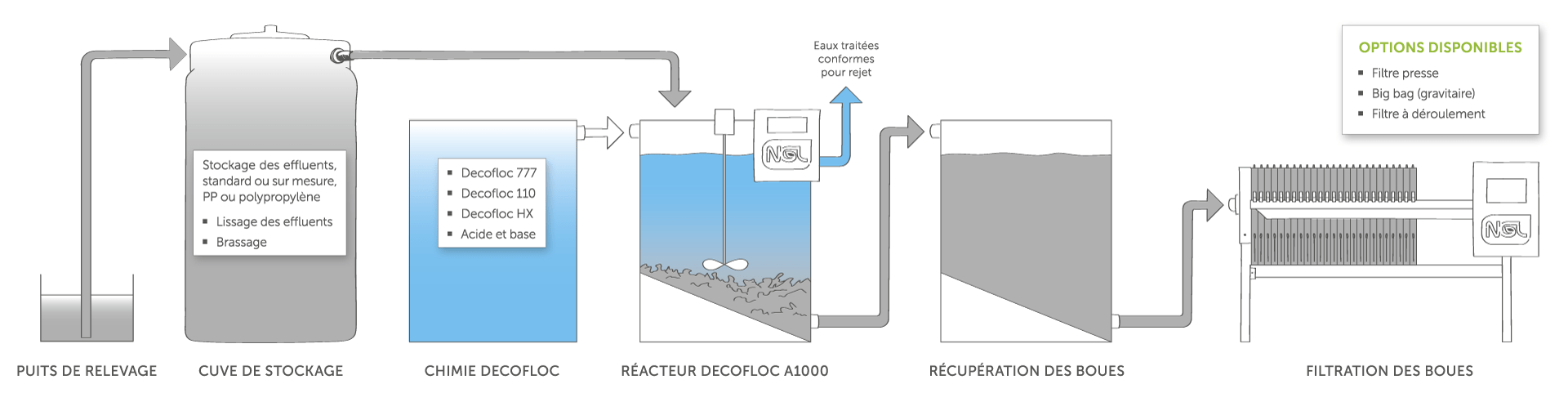

They are largely removed by pH correction, filtration, decantation and coagulation/flocculation stages. When COD exceeds 2000 mg/L, evapo-concentration systems are generally used.

OPERATING SCHEME

COLLOIDAL PARTICLES AND IONIZED METALS

Colloidal particles are characterized by two key features: firstly, they have a very small diameter (from 1 nm to 1 µm) – and secondly, they are electronegatively charged, generating inter-colloidal repulsive forces. These two points give colloids an extremely low sedimentation rate (which can even be considered zero in the context of water pre-treatment).

Coagulation-flocculation is a two-stage process that overcomes this lack of sedimentation. This technique tackles the two characteristics – mentioned above – that make natural elimination of colloidal particles impossible.

COAGULATION

In the first stage, coagulation, by adding metal salts (generally iron or aluminum), eliminates intercolloidal repulsion: metal cations (Al3+ and Fe3+) bind to the colloids and neutralize them. Colloidal particles can now meet.

FLOCULATION

Secondly, flocculation tackles the problem of small colloid diameters. The real problem is mass, which prevents natural sedimentation that can be used for treatment. The solution exploited by flocculation is to provoke agglomeration of colloidal particles by adding flocculant. This agglomerate of colloids, known as floc, then has sufficient mass to settle out. The added flocculant is generally an organic or natural polymer, which acts as a glue between the colloids.

FILTERING

The flocs are filtered, either through pockets (gravity filtration) or a filter press to obtain drier sludge.

FAQ ON INDUSTRIAL WASTEWATER TREATMENT PLANTS

What is an industrial WWTP?

An industrial wastewater treatment plant is a facility designed to treat wastewater generated by industrial activities. It uses a variety of physical, chemical and biological processes to remove pollutants before discharging the water back into the environment.

Why is industrial wastewater a problem?

Industrial wastewater contains substances and concentrations of synthetic organic compounds that are higher than those found in domestic wastewater. Some of these substances are very long-lived, accumulate in organisms, or can promote the development of resistance, for example to antibiotics.

Can modern WWTPs eliminate all industrial pollutants?

Even modern WWTPs cannot eliminate all synthetic compounds from the pharmaceutical and chemical industries. Research shows that treated industrial wastewater sometimes contains up to 15 times more substances and higher concentrations of synthetic organic compounds than domestic wastewater.

What are the limitations of industrial wastewater treatment?

Limitations include the difficulty of dealing with the great chemical diversity specific to companies’ manufacturing processes, as well as the inability to capture certain substances that are not looked for in standard analyses.

What measures can improve efficiency?

Strategies to improve WWTP efficiency include modifying wastewater treatment practices within companies, innovating treatment technologies and adopting legal regulations, as with NGL solutions.

How does wastewater treatment work in an industrial WWTP?

Treatment can include several stages, such as primary treatment (analysis, neutralization, settling), biological degradation in several phases to break down pollutants, and quaternary treatment to eliminate the last suspended solids and excess phosphates.

What is micropollutant treatment?

Since 2016, some plants have been equipped to specifically treat micropollutants, with technologies such as activated carbon, to further reduce harmful substances released into the environment, a technology present at NGL.

Do WWTPs produce waste?

Yes, WWTPs generate sewage sludge, which must be treated and disposed of in accordance with legislation. Disposal methods often include incineration, sometimes with energy recovery.

What is the role of controls and standards for WWTPs?

Controls and standards ensure that WWTPs operate efficiently and in compliance with environmental requirements. They help monitor the quality of treated water and assess the efficiency of treatment processes.

Can the quality of water treated by industrial WWTPs be improved?

Yes, thanks to technological innovations, better monitoring of discharged substances, and the adoption of best industrial practices, it is possible to significantly improve the quality of water treated by industrial WWTPs. Contact NGL to find out more.