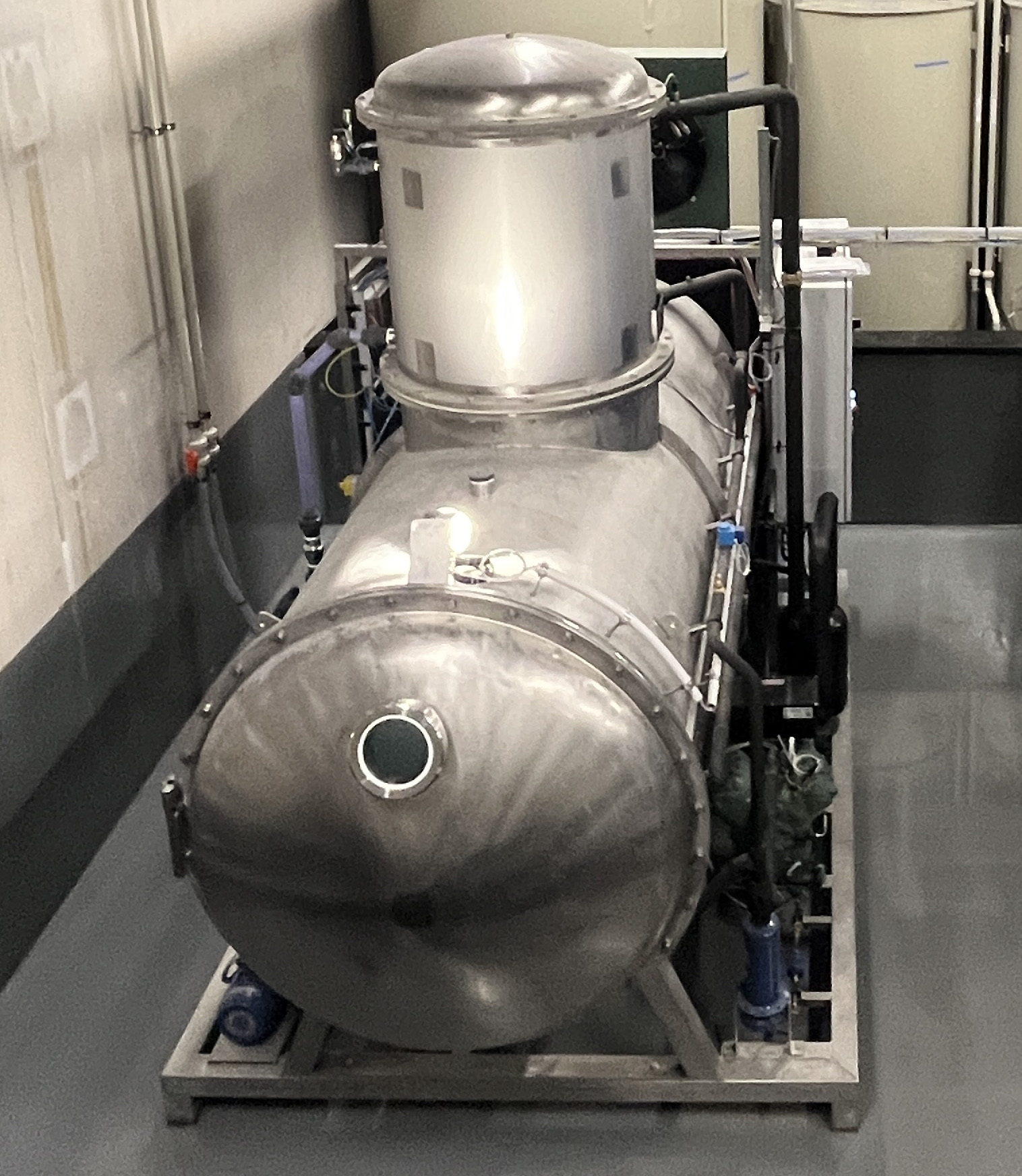

In industrial wastewater treatment, evapo-concentrators play a crucial role in reducing effluent volumes, concentrating pollutants and enabling more economical and environmentally-friendly waste management. This type of equipment is an effective solution for companies faced with growing environmental demands and high liquid waste disposal costs.

Adopt an evapo-concentrator for industrial wastewater

- Significant reduction in effluent volumes: Evaporation can reduce effluent volumes by up to 90%, significantly reducing the cost of transporting and treating liquid waste. Pollutants are concentrated in a fraction of their original volume, making them easier to manage.

- Compliance with environmental regulations: Industrial wastewater discharge standards are becoming increasingly stringent, particularly for the chemical, pharmaceutical and food industries. The evapo-concentrator enables effluents to be treated to purity levels that comply with regulations.

- Water recovery and reuse: Evaporated water is condensed into a distillate, which can be reused in industrial processes (cleaning, cooling, etc.) or discharged with low environmental impact. Reduced drinking water consumption and associated costs.$

- Energy efficiency thanks to vacuum technology: vacuum evaporators enable evaporation temperatures to be lowered (often to 30-50°C), thus reducing energy consumption compared with conventional evaporators. Some models use renewable energy sources or heat recovery systems for even greater efficiency.

- Reduced long-term operating costs: Although the initial investment may be high, the reduction in volumes to be treated and water recovery enable significant savings on disposal and supply costs. Limits the need for water treatment chemicals.

Questions to ask before purchasing an evapo-concentrator :

- How much effluent does your business generate?

- What types of pollutants are present in your wastewater?

- Would you like to reuse distilled water or reduce waste transport costs?

If you are based in France or Switzerland and need a solution for the treatment of your industrial water, contact our NGL Water Technology teams.